Injection molding, ever heard of it? It’s like the unsung hero of modern manufacturing. If you’ve got a plastic product in your hand, chances are, it was made using this process. But what exactly is injection molding, and why is it such a big deal?

What is Injection Molding?

In the simplest terms, injection molding is a manufacturing process used to produce parts by injecting molten material into a mold. Think of it like baking a cake, where the mold is your cake pan, and the molten material is your batter. Once the material cools and solidifies, you’ve got yourself a perfectly shaped part.

Importance of Injection Molding in Manufacturing

Injection molding is crucial in today’s manufacturing world. It's the go-to method for mass-producing high-quality, consistent parts. From automotive components to tiny medical devices, injection molding is everywhere.

History of Injection Molding

Early Beginnings

Injection molding has come a long way. It all started in the late 19th century when John Wesley Hyatt invented the first injection molding machine. He was trying to find a way to make billiard balls without using ivory. Ingenious, right?

Evolution Over the Years

Fast forward to today, and injection molding has evolved into a highly sophisticated process. Modern machines are capable of producing incredibly intricate parts with high precision and speed.

The Injection Molding Process

Step-by-Step Overview

Clamping: The mold is securely closed.

Injection: Molten plastic is injected into the mold cavity.

Cooling: The plastic cools and solidifies.

Ejection: The finished part is ejected from the mold.

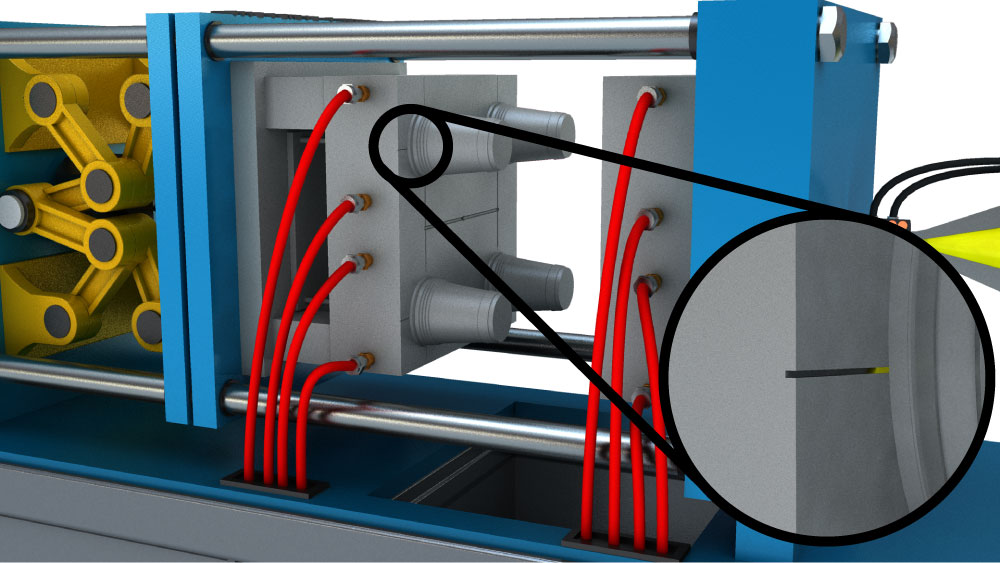

Key Components Involved

The Mold: The heart of the process, designed specifically for the part being made.

The Machine: Includes the clamping unit and the injection unit.

The Material: Typically plastic, heated until it’s molten.

Types of Injection Molding Machines

Hydraulic Injection Molding Machines

These are the traditional workhorses of the injection molding world. They use hydraulic systems to exert the pressure needed to inject the molten material.

Electric Injection Molding Machines

A more modern alternative, these machines use electric motors. They’re faster, more precise, and energy-efficient.

Hybrid Injection Molding Machines

As the name suggests, these machines combine the best of both worlds. They offer the power of hydraulics and the precision of electrics.

Materials Used in Injection Molding

Thermoplastics

The most common materials used. They’re recyclable and include types like polyethylene and polypropylene.

Thermosetting Plastics

Once cured, these materials can’t be melted again. They’re used for parts that need to withstand high temperatures.

Elastomers

These are like rubber and are used for flexible, durable parts.

Design Considerations for Injection Molding

Part Design

The part’s design needs to consider the material flow, cooling time, and ease of ejection.

Mold Design

The mold must be designed for durability and to ensure it can produce the part accurately and consistently.

Material Selection

Choosing the right material is crucial for the part’s performance and durability.

Advantages of Injection Molding

Efficiency and Speed

Injection molding is incredibly efficient, capable of producing thousands of parts per hour.

Precision and Consistency

Each part produced is identical, ensuring high-quality and reliable performance.

Cost-Effectiveness

While the initial cost is high, the per-part cost is very low, making it economical for mass production.

Disadvantages of Injection Molding

High Initial Cost

The cost of the mold and machine setup can be substantial.

Design Limitations

Some complex designs may be difficult or impossible to produce.

Material Constraints

Not all materials can be used in injection molding.

Applications of Injection Molding

Automotive Industry

From dashboards to bumpers, injection molding is used extensively in car manufacturing.

Consumer Goods

Think of all the plastic products you use daily – many of them are made via injection molding.

Medical Devices

Precision is crucial here, and injection molding delivers.

Electronics

From housings to tiny components, injection molding is indispensable in electronics.

Innovations in Injection Molding

Micro Injection Molding

Perfect for producing tiny, intricate parts used in medical and electronic applications.

3D Printing Integration

Combining 3D printing with injection molding opens up new possibilities for rapid prototyping and production.

Biodegradable Materials

With a focus on sustainability, biodegradable materials are becoming more popular.

Common Defects in Injection Molding

Warping

Parts can warp if they cool unevenly.

Sink Marks

These occur when the inside of the part cools slower than the outside.

Flash

Excess material that seeps out of the mold cavity.

Short Shots

Incomplete parts due to insufficient material filling the mold.

Troubleshooting Injection Molding Issues

Identifying Problems

Regular inspection and monitoring are crucial.

Solutions and Preventive Measures

Adjusting machine settings, improving mold design, and using higher-quality materials can help.

Environmental Impact of Injection Molding

Waste Management

Efficient waste management practices are essential.

Sustainable Practices

Using recycled materials and reducing energy consumption are key.

Recycling in Injection Molding

Recycled plastics are increasingly used in the process.

Future of Injection Molding

Technological Advancements

Automation and AI are set to revolutionize the industry.

Market Trends

The demand for injection-molded products continues to grow.

Challenges Ahead

Environmental concerns and the need for more sustainable practices are significant challenges.

Conclusion

Injection molding is a cornerstone of modern manufacturing, offering unmatched efficiency, precision, and versatility. While there are challenges, innovations and sustainable practices promise a bright future for this essential process.

FAQs

Q. What is injection molding most commonly used for?

Ans: Injection molding is used for mass-producing plastic parts, from automotive components to medical devices.

Q. Can injection molding be used for metal parts?

Ans: Yes, a variation called metal injection molding (MIM) is used for producing small, complex metal parts.

Q. How long does it take to produce a part using injection molding?

Ans: It can range from a few seconds to a few minutes, depending on the part's complexity and size.

Q. What are the cost factors in injection molding?

Ans: The primary costs are the mold creation, material, and machine operation. While the initial setup is expensive, the cost per part is low.

Q. Is injection molding environmentally friendly?

Ans: Efforts are being made to improve sustainability, such as using recycled materials and biodegradable plastics. However, the process still has environmental impacts.