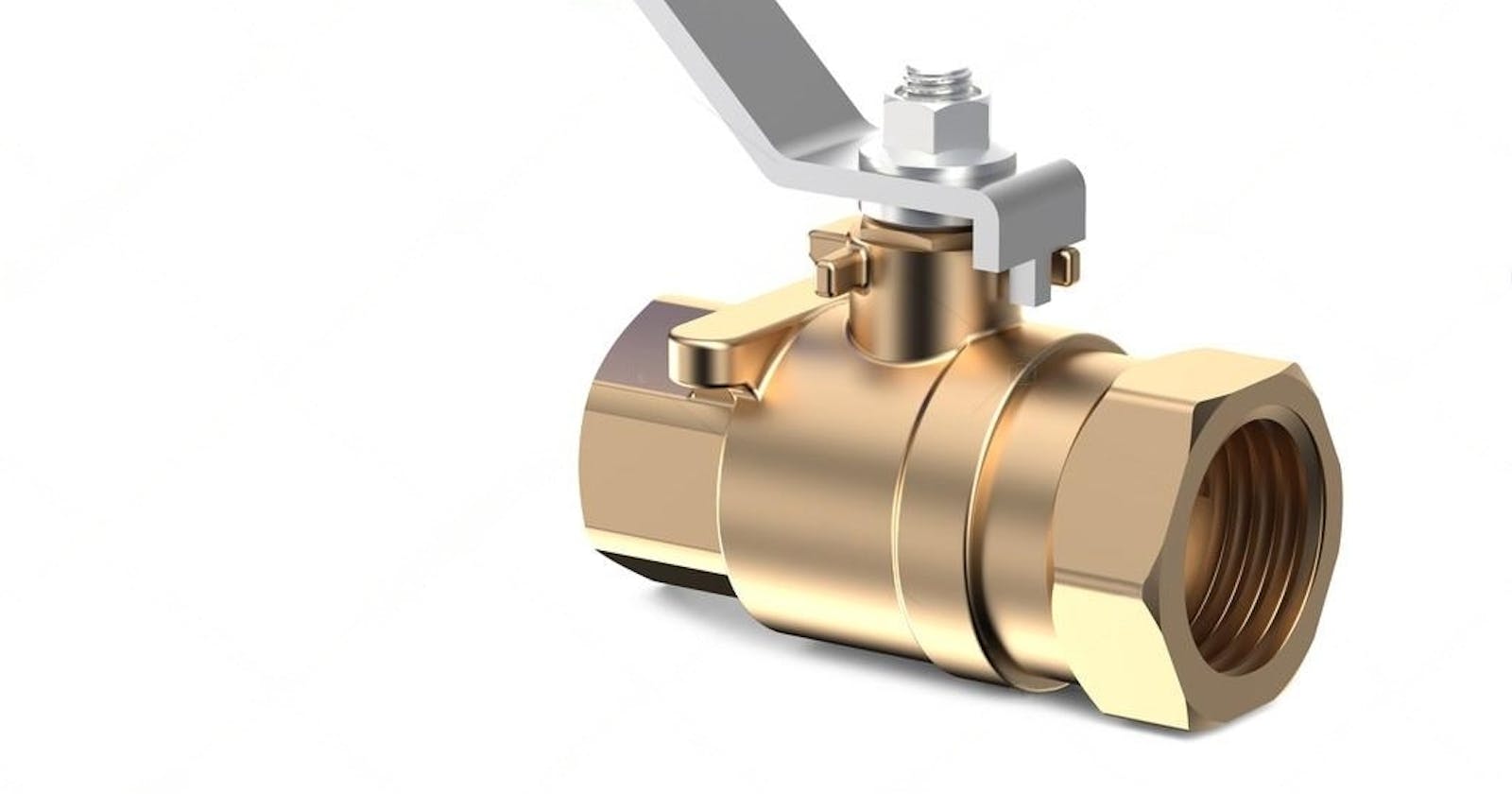

Union Ball Valves are one type of ball valve which has an union connection at both sides of the valve body. The union connection permits ease of repair and replacement of the valve, without disassembling whole pipeline. The union connection is comprised of two threaded ends that are joined by a nut as well as gasket. This makes for the security of a leak-proof seal, which is easily removed at any time.

Construction of Union Ball Valves

Ball valves of the union are constructed of various components, including brass, stainless steel and PVC. The valve body is composed of three major components: the body, the stem, and the ball. It is the shell, which is home to the stem and ball. It is also the main part that controls how fluid flows. It is the branch component that connects the handle with the ball, and controls the ball's movements.

The ball is typically constructed of durable, complex ceramic material or stainless steel. The stem is usually constructed of brass or stainless steel. Based on the purpose of the application and the type of fluid being carried the valve body as well as other components may be constructed out of various components.

How Union Ball Valves Work

Union ball valves function by rotating a ball through the port or hole that fluid can flow through. When the ball is rotated parallel to the pipe, the port closes and the flow ceases. If the ball is rotated perpendicular to the pipe's direction, it's port will be open and flow can be allowed. Union ball valves are operated manually, electrically or pneumatically.

Applications of Union Ball Valves

Union ball valves are utilized in a variety of instances where a secure leak-proof seal is needed. They are widely employed in the pharmaceutical, chemical petroleum, gas and oil as well as food and beverage and industries of water treatment. They also are used in commercial and residential plumbing systems to regulate gas and water flow.

Advantages of Union Ball Valves

Union Ball Valves have numerous advantages over other types of valves, such as:

Simple installation and maintenance The union connection permits for simple maintenance and installation without disassembling all pipelines.

Leak-proof seal The union connection offers a leak-proof, reliable seal that is easy to removed.

Port design complete Union ball valves feature an entire port design, allowing maximum flow and a low tension drop.

Large temperature range Ball valves from Union can work in a range of temperatures.

Disadvantages of Union Ball Valves

High Cost. One of the major drawbacks associated with union ball valves are their price. They are typically more costly than other kinds of valves.

Limited Chemical Compatibility Union ball valves also have limitations in chemical compatibility.

Limited Flow Control Another drawback for union ball valves are their lack of flow control.

Installation and Maintenance of Union Ball Valves

Maintenance and installation of union ball valves need certain steps in order to ensure maximum performance and durability. Here are the suggested procedures to install and maintain union ball valves.

Installation:

Make sure you have a valve that is suitable for the intended application as well as operating requirements.

Clean the pipeline thoroughly of any foreign or soiled materials prior to installing.

Attach the valve to the pipeline, making sure that the valve is aligned to flow direction, and that the connection at the end is properly secured.

Find any leaks by pressing down on the system, and then inspecting the valve and connections to see if there are any indications of leakage.

Conduct a test cycle to make sure that the valve functions efficiently and smoothly.

Maintenance:

Check the valve regularly for signs of wear or damage such as leaks or corrosion.

Make sure to lubricate your valve frequently for smooth and efficient operation. to prevent seizing or sticking.

Cleanse the valve and the surrounding zone of any dirt or debris accumulation that may hinder the proper operation of the valve.

Replace worn or damaged parts such as seals and bearings.

Conduct regular test cycles to ensure that the valve is functioning effectively and efficiently.

If you follow these steps for installation and maintenance to ensure the highest performance and durability.